Advantages of vacuum membrane press machine

2024-01-29

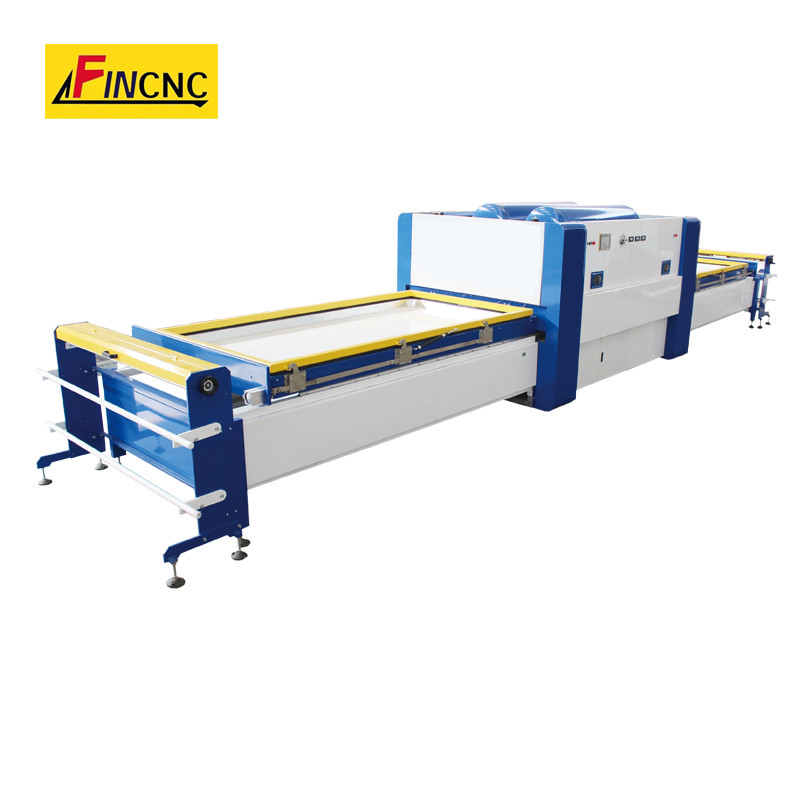

A vacuum membrane press machine, also known as a vacuum press membrane machine or vacuum membrane press, is a type of equipment used in woodworking and other industries for laminating and shaping materials. Here are some advantages of using a vacuum membrane press machine:

1. Uniform Pressure Distribution: The vacuum membrane press applies uniform pressure over the entire surface of the workpiece, ensuring consistent and even lamination. This helps in achieving high-quality results and preventing uneven bonding.

2. Versatility: Vacuum membrane presses are versatile and can be used for various applications, including veneering, laminating, and molding. They can handle different shapes and sizes of workpieces, making them suitable for a wide range of projects.

3. Enhanced Adhesion: The vacuum process helps in achieving better adhesion between the material and the substrate. This is crucial for applications like laminating wood veneers or applying decorative films to achieve a smooth and durable finish.

4. Complex Shape Handling: Vacuum membrane presses can handle complex shapes and contours, allowing for the production of intricate and customized components. This is particularly beneficial in industries such as furniture manufacturing, where complex designs are common.

5. Time and Cost Efficiency: The vacuum membrane press can streamline the lamination and molding process, reducing the time required for production. This efficiency can result in cost savings for manufacturers, especially in large-scale or repetitive production scenarios.

6. Reduced Waste: The precise application of pressure and the ability to conform to the shape of the workpiece contribute to reduced material waste. This is important for optimizing material usage and minimizing costs.

7. Ease of Operation: Vacuum membrane presses are relatively user-friendly and do not require highly specialized skills for operation. This makes them accessible to a range of users, from small workshops to larger manufacturing facilities.

8. Consistent Results: The controlled environment created by the vacuum press contributes to consistent and repeatable results. This is essential for maintaining quality standards in manufacturing processes.

9. Improved Safety: Vacuum membrane presses often come with safety features such as emergency stop buttons and safety interlocks, ensuring a safer working environment for operators.

10. Clean and Neat Finish: The vacuum process helps in eliminating air bubbles and imperfections, resulting in a clean and neat finish on the laminated or molded workpiece.

While vacuum membrane press machines offer numerous advantages, it's important to choose the right machine for specific applications and ensure proper maintenance to maximize efficiency and longevity.