What are the facts about acrylic sheets?

2024-12-05

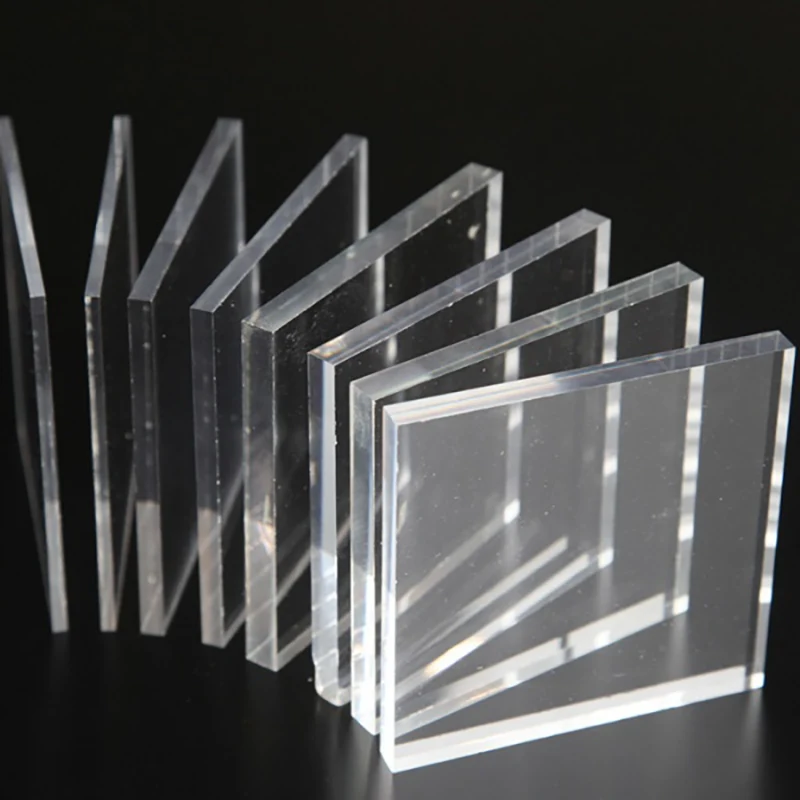

Acrylic sheets, also known as Plexiglass, are a popular material due to their versatility, durability, and aesthetic appeal. They are widely used across various industries, including construction, interior design, automotive, and signage. Below are some key facts about acrylic sheets:

1. Composition

- Material: Acrylic sheets are made from polymethyl methacrylate (PMMA), a lightweight, transparent thermoplastic.

- Variants: Available in extruded or cast forms, with cast acrylic being more durable and optically clear than extruded acrylic.

2. Transparency

- High Clarity: Acrylic sheets offer up to 92% light transmission, making them clearer than glass.

- UV Resistance: They resist yellowing and maintain transparency when exposed to sunlight.

3. Strength and Durability

- Impact Resistance: Acrylic sheets are 10 times more impact-resistant than glass, making them safer and less prone to shattering.

- Weather Resistance: They withstand harsh weather conditions, including rain, snow, and prolonged UV exposure, making them suitable for outdoor use.

4. Weight

- Lightweight: Acrylic is 50% lighter than glass, reducing structural load and making it easier to transport and install.

5. Versatility

- Wide Applications: Used in signage, aquariums, furniture, protective barriers, and more.

- Customizable: Available in various thicknesses, colors, finishes, and patterns. They can also be easily cut, shaped, or engraved.

6. Thermal Properties

- Heat Resistance: Acrylic sheets can withstand moderate heat but may warp or soften at temperatures above 160°F (71°C).

- Thermoformable: They can be heated and molded into complex shapes, allowing for creative applications.

7. Maintenance

- Easy to Clean: Requires only mild soap and water for cleaning. Avoid harsh chemicals like ammonia, which can cause damage.

- Scratch Resistance: While durable, acrylic is more prone to scratching than glass. Polishing can often remove minor scratches.

8. Eco-Friendliness

- Recyclable: Acrylic sheets can be recycled and repurposed into new products.

- Sustainability: Producing acrylic generates fewer emissions compared to some other plastics.

9. Cost

- Affordable Alternative: Acrylic sheets are generally more cost-effective than glass while offering similar or better functionality.

- Long Lifespan: Their durability and resistance to environmental factors provide excellent long-term value.

10. Safety

- Shatter-Resistant: Unlike glass, acrylic does not break into sharp, dangerous shards, making it safer in various applications.

- Protective Barriers: Commonly used in sneeze guards, shields, and other safety partitions.

11. Limitations

- Scratch Susceptibility: Acrylic can scratch more easily than glass but can often be polished to restore clarity.

- Lower Heat Resistance: Not suitable for applications involving very high temperatures.

- Static Electricity: Acrylic tends to attract dust due to static electricity.

12. Common Uses

- Signage and Displays: Popular for its clarity and ability to be easily shaped.

- Home Décor: Used in furniture, partitions, and picture frames.

- Aquariums and Terrariums: Offers a clear, lightweight alternative to glass.

- Automotive and Aerospace: Used in windshields, windows, and instrument panels.

- Medical Applications: Found in incubators, protective shields, and medical devices.

Conclusion

Acrylic sheets are an excellent choice for applications requiring clarity, durability, and design flexibility. Their wide range of uses and benefits, combined with their affordability, make them a favored material in many industries. Understanding their properties helps in selecting the right type and thickness for specific projects.