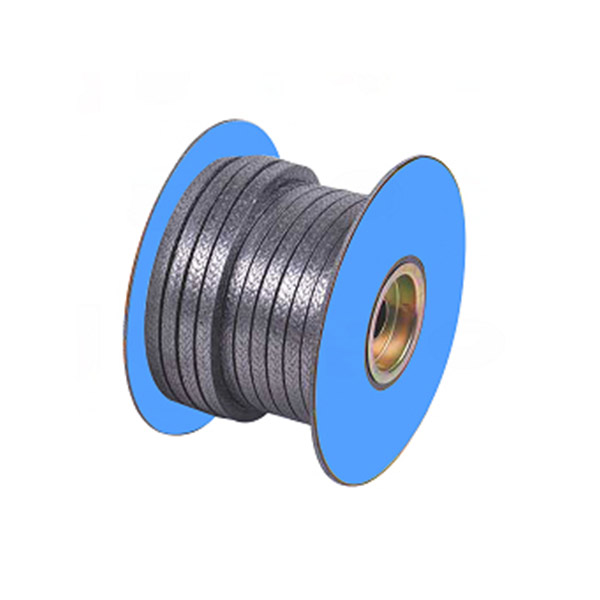

The Brief Introduction to Flexible Graphite Packing with Corrosion Inhibitor

Flexible Graphite Packing with Corrosion Inhibitor is a type of sealing material that is commonly used in high-temperature and high-pressure applications such as pumps, valves, and turbines. The packing is designed to prevent leaks by filling the gaps between the moving parts of the equipment and cr......

Send Inquiry

Product Description

Flexible Graphite Packing with Corrosion Inhibitor is a type of sealing material that is commonly used in high-temperature and high-pressure applications such as pumps, valves, and turbines. The packing is designed to prevent leaks by filling the gaps between the moving parts of the equipment and creating a tight seal.

The production process for Flexible Graphite Packing with Corrosion Inhibitor typically involves the following steps:

1. Material Selection: First, high-quality graphite fibers are selected, which are then processed to form graphite yarn.

2. Impregnation: The graphite yarn is impregnated with a corrosion inhibitor such as PTFE or silicone oil. This process enhances the sealing performance of the packing and also provides resistance to corrosion and abrasion.

3. Braiding: The impregnated graphite yarn is then braided into the desired packing size and shape. The braiding process ensures that the packing has the required strength and flexibility to be installed into the equipment.

4. Coating: A final coating may be applied to the packing to improve its performance and durability. The coating may be made of materials such as PTFE, silicone oil, or other polymers, which provide additional resistance to corrosion, abrasion, and high temperatures.

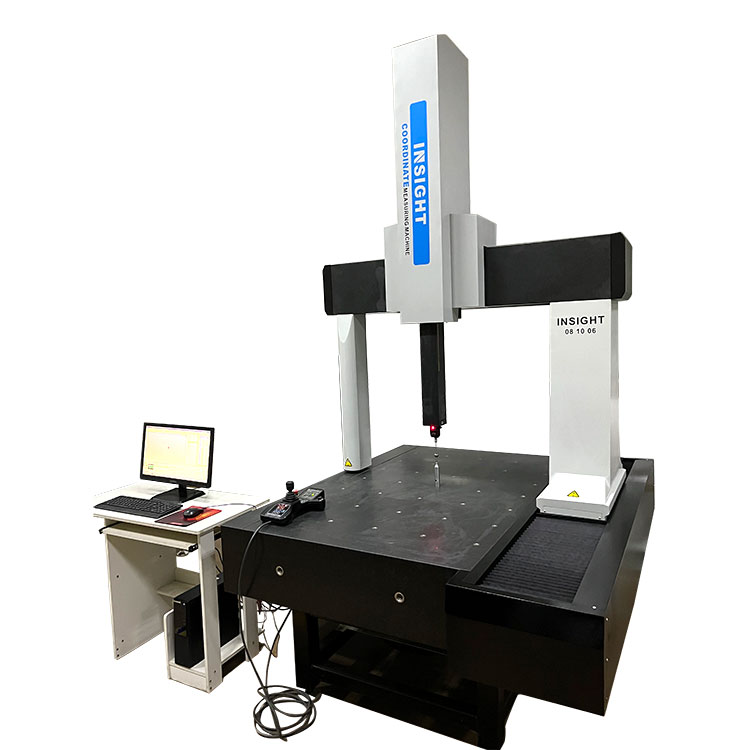

5. Quality Control: The final product is subjected to rigorous quality control measures to ensure that it meets the required specifications and standards. The packing is typically tested for its strength, flexibility, and resistance to temperature and chemical corrosion.

Overall, the production of Flexible Graphite Packing with Corrosion Inhibitor requires expertise and precision to ensure that the final product can withstand the harsh conditions of high-temperature and high-pressure applications. The packing must be durable, flexible, and resistant to corrosion and abrasion to ensure that it provides a reliable sealing solution.